Waste Heat Recovery

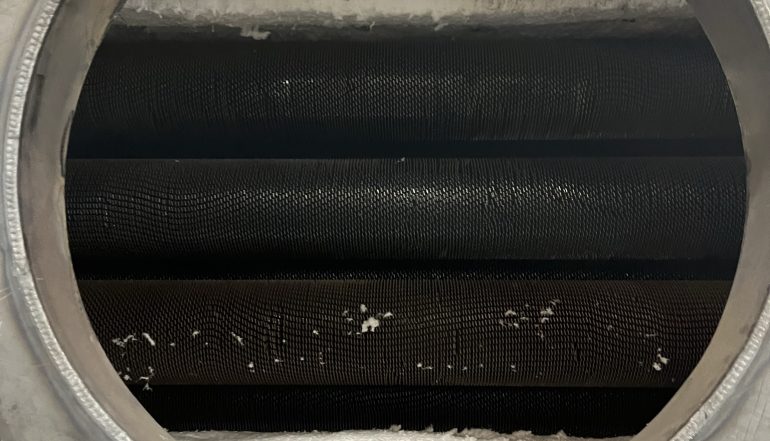

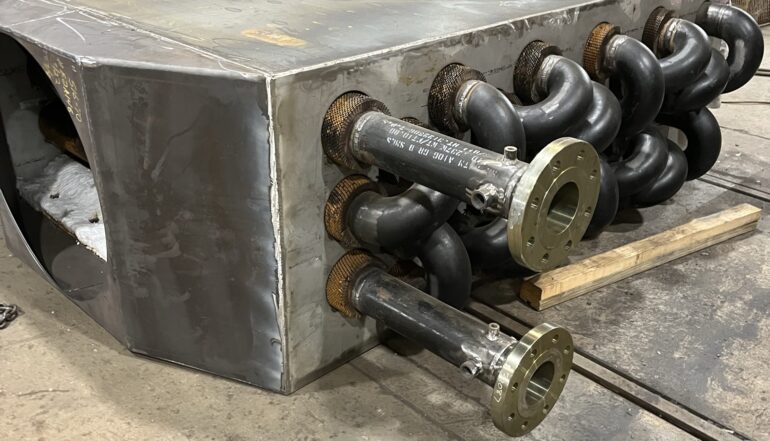

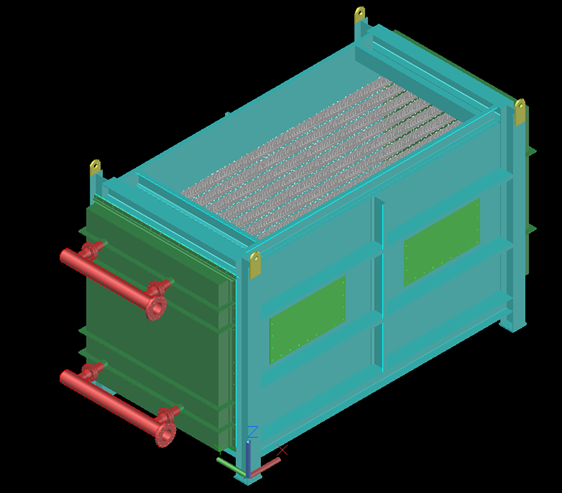

American Thermal specializes in crafting tailored High-Temperature Waste Heat Economizers designed to capture heat from the exhaust of industrial equipment, including incinerators, oxidizers, turbines, and gasifiers. This recovered heat is repurposed for various industrial processes. Essentially, waste heat recovery involves reclaiming and reusing heat energy that would otherwise be wasted.

Our expertise in this technology mirrors that of the economizer section in American Thermal Hot Oil Heaters, enabling us to design and simulate the performance of our Waste Heat Economizers effectively.

Most applications involve heating hot oil, glycol fluid, and, in some cases, even asphalt itself. The Waste Heat Economizer swiftly repays its investment by dramatically reducing energy consumption in heating equipment.

- Increased Efficiency

- Resource Conservation

- Waste Reduction

- Reduced Plant Operating Costs

- Reduced Plant Energy Consumption

- Repurpose Dangerous Emissions

Benefits of American Thermal

Increased Efficiency

In large-scale settings such as manufacturing facilities and production plants, the adoption of waste heat recovery systems is crucial for boosting efficiency. This minor adjustment can yield significant efficiency improvements, making a profound impact both at an industry level and on a large scale.

Resource Conservation

Waste heat recovery is a great method for plants and facilities to conserve resources. Implementing a waste heat recovery system can, in some cases, eliminate the need for another heat source entirely, making a significant difference in energy conservation.

Waste Reduction

Redirecting waste gas and utilizing it as a heat source can reduce the amount of waste produced by a facility and released into the atmosphere.

Reduce Plant Operating Costs

Plant and facility managers are consistently looking for ways to decrease their expenses and increase their profitability. Implementing a waste heat recovery system is a straightforward way to save money on your facility’s operating costs.

Reduce Plant Energy Consumption

As mentioned earlier, companies of all types have leveraged waste heat recovery technology to cut waste and boost efficiency. On a plant level, implementing a system like this can significantly reduce your plant’s energy consumption.

Repurpose Dangerous Emissions

While waste heat recovery can help to conserve energy and reduce waste, it can also help to handle the dangerous waste generated from various processes. Some waste gases are dangerous and toxic. As a result they cannot be released directly into the atmosphere and must be incinerated first. Instead of disposing of these incinerated gases, a waste heat recovery system enables you to repurpose them in a way that can help to contribute to your facility’s productivity.